A couple days ago I was doing my kitchen chores and realized I was out of food (or sealing) clips.

And I needed those ASAP.

So the choice was to either:

- stop doing the important stuff (that being actually cleaning up and sorting the inventory) and go out looking for some sealing clips or…

- spend 10-15 minutes setting up a print job and 3D print some clips right at home!

The latter option was so much more convenient and fun, that I obviously went with it. And by the time I was done, the clips were done as well, and I made use of them straight away.

Afterwards I realized that this provided a great opportunity for a brief post on the topic of 3D printing and my experience with it. As well as another look at the age-old question: "What is a consumer 3D printer actually useful for?"

My First 3D Printer

Oh, boy…

This section will be brief, since even thinking about the old machine gives me a headache and makes my blood boil…

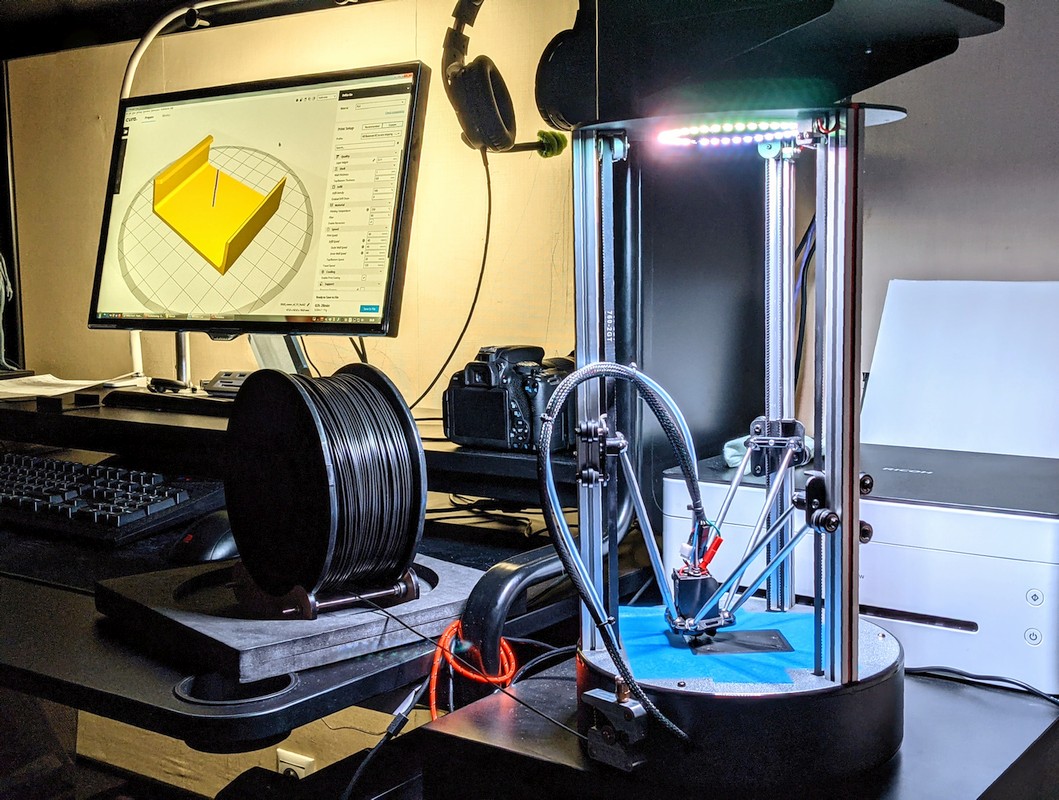

About 5 years ago I got an idea to sculpt and 3D print some anime figures. Back then I didn't have enough room for a "traditional" flatbed 3D printer, so I opted to go with a "delta"-type device which takes much less space horizontally, whilst being quite a bit taller than a flatbed machine. The printer I went with was a 2nd revision Delta Go.

Long story short, it suuuuucked.

It would regularly have issues with filament feeding, hot end clogging, prints not sticking to the non-heated bed. Yes, a non-heated bed! You can see on the photo how the print surface is covered with 3M painter's tape, a consumable. Believe it or not, but this is intentional, since there's no other way to stick the first layer to the non-stick non-heated aluminum surface. The tape "grabs on" to the hot extruded filament and this is meant to help hold the print in place.

Except it doesn't!

Oh, how many times did my prints warp, distort or outright fell off the surface, and I ended up with a horrible mess instead of a useful print. Delta-type printers are also notorious for creating concentric artifacts on straight surfaces because of the rounding errors during the conversion from Cartesian into polar coordinates for printing.

Looking back, I would say the success rate of printing with Delta Go was 10-20% at best. You can imagine how demoralizing and aggravating it was to see a 90% complete print job fail because the printer's filament feeder would suddenly decide to start skipping, or the hot end would clog, or the print would start unsticking from the bed… It was so bad that after several months of struggling with the machine I shelved the figure printing idea indefinitely and put the damn thing far, far away, hoping to never have to to take it out again.

The New 3D Printer

Year 2022 began with a new exciting project — getting to know microcontrollers, which ultimately led to me designing a Smart Weather Station, which needed… You guessed it — a case. And, well… After dusting off the old Delta Go and going though a whole week of the worst 3D printing experience anyone had ever had, I decided to finally wave goodbye to the useless machine and shelled out for a new one.

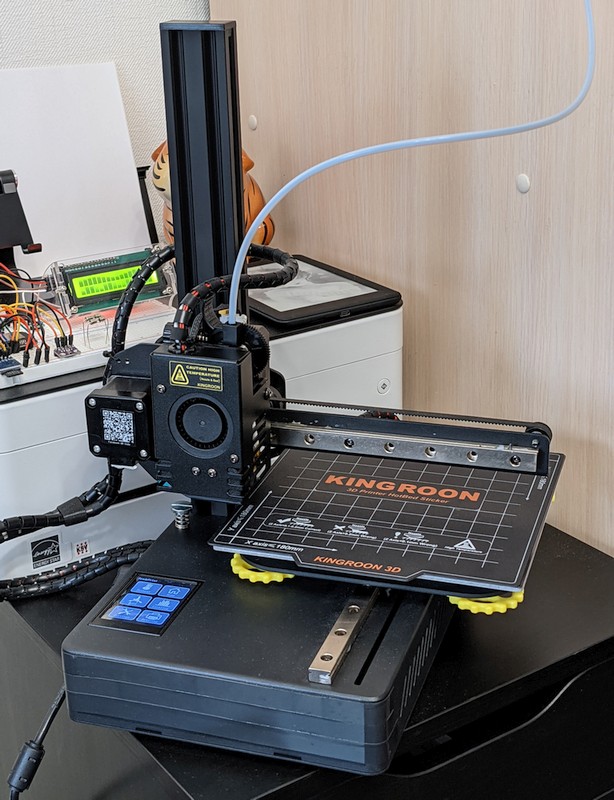

It didn't take long to find a replacement. All I needed was a low-cost device with at least 150x150x150 cm print area, a properly heated print bed and a direct filament feeding mechanism (in contrast to the one used in the Delta Go).

Hardware

After a couple hours of research I ended up ordering Kingroon KP3S 3D. Little did I know, this model was at that time considered one of the best budget printers available on the market! And it deserves every single bit of praise, indeed!

I won't do a full review, since it's been tested to death by more competent people on the web. If you're interested, this one pretty much sums up my experience with the machine:

I got it in June 2022, and up until now haven't had a single mechanical or software issue! For a printer that costs less than 200 bucks (with shipping!) this one is an absolute no-brainer.

Just make sure not to purchase the newer Kingroon KP3S Pro model! It's an overpriced and terribly engineered pile of trash according to most reviews on the web, as well as one of the loudest machines out there due to an idiotic cooling duct design. Come to think of it... No other Kingroon printers are worthy of a purchase, including the newest Kingroon KLP1. Seems like KP3S 3D was their one lucky break, and they failed to follow it up with anything of value. Oh well.

Also, make sure to never leave this printer alone when it's printing. As far as I can tell, KP3D lacks thermal runaway protection. So like many other cheaper printers it's should only be running with someone periodically checking up on the process to guarantee successful and safe printing.

Update 14.01.2024: after hundreds of hours of printing and tons of prints produced, the extruder motor died in my KP3S. Even though it can be replaced I think I've had enough time with this model and will later get something a bit more advanced. Rest in peace, my dear printer, you were awesome.

Software

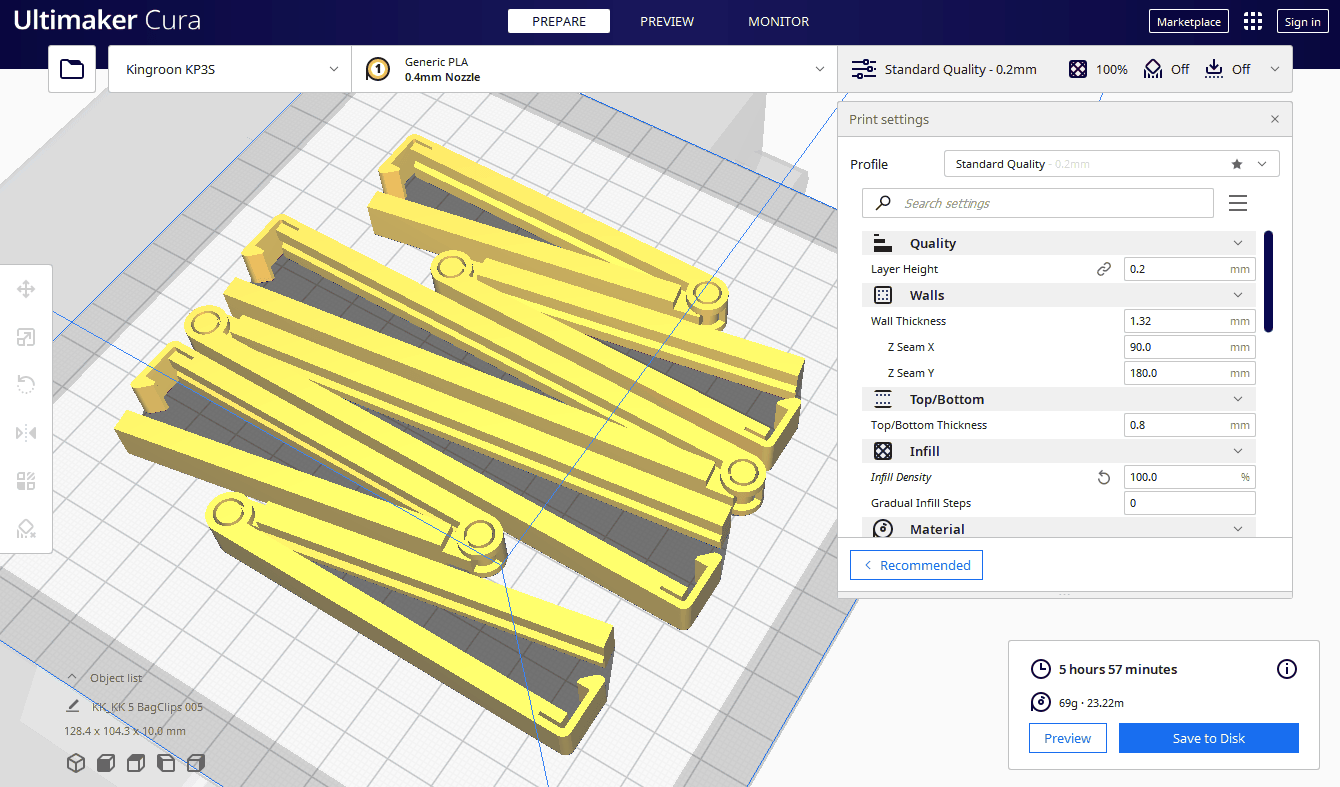

Software-wise, the latest versions of Ultimaker Cura fully support hundreds of 3D printer models out of the box, and Cura is the slicer I usually use to turn my meshes into GCODE files for printing. I also tried PrusaSlicer and even though the current version didn't come with a profile for KP3S, I was able to find one online and it worked fine. Still, I find PrusaSlicer's UI/UX experience much more involved compared to Cura, so I don't use it that much.

With new hardware and software combined, my 3D printing success rate went all the way up to 90%! And this time, the vast majority of the failed prints were actually my fault! It was either due to insufficient bed leveling, lack of printing supports (or some other print pattern-related issue), improper hot end/print bed temperatures and such, but never — sudden issues with filament feeding or the hot end getting jammed because it "felt like it".

To sum up:

It just works©

(until it breaks)

Even a cheap device will allow you to produce a product or two. It won't last, but can provide a good entry point into the the world of 3D printing. So if you're interested, I can give an advice or two after all…

Print Monitoring

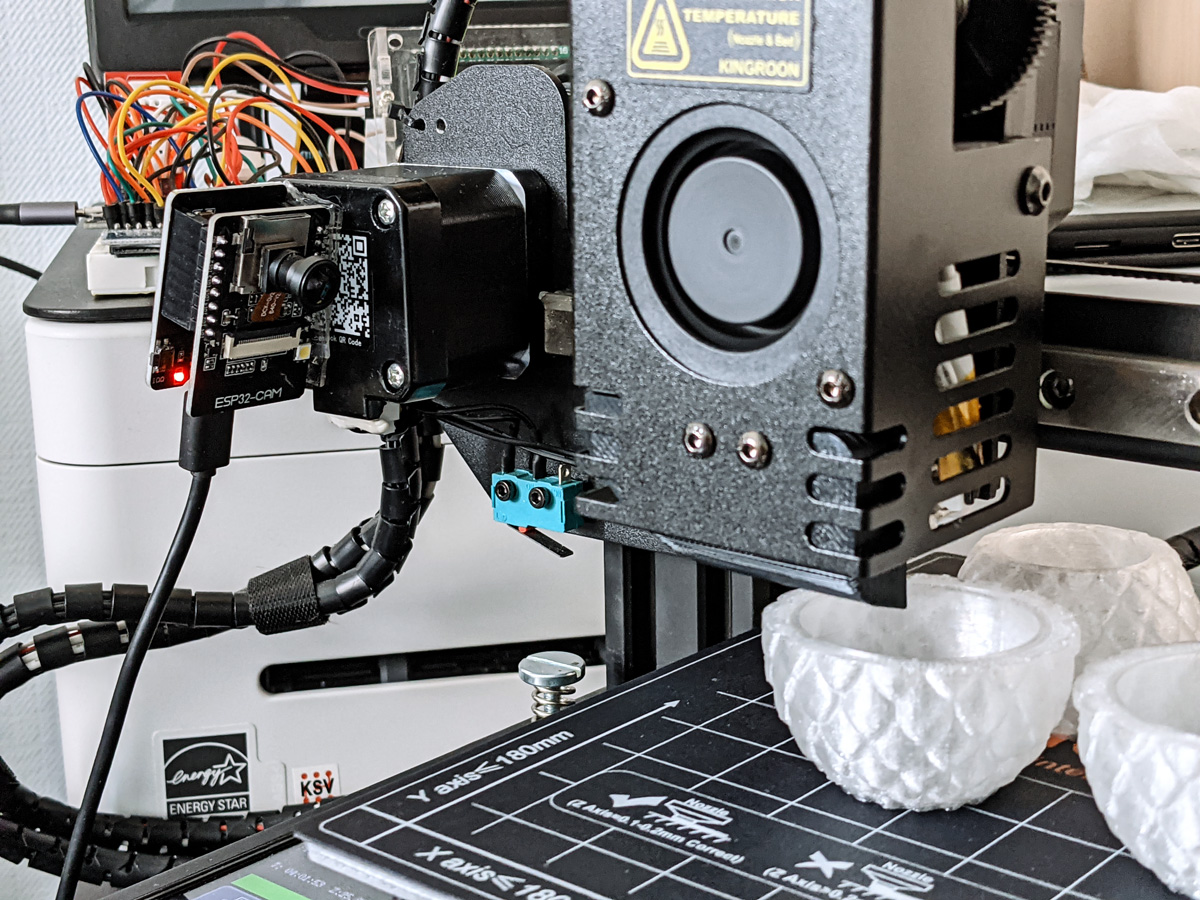

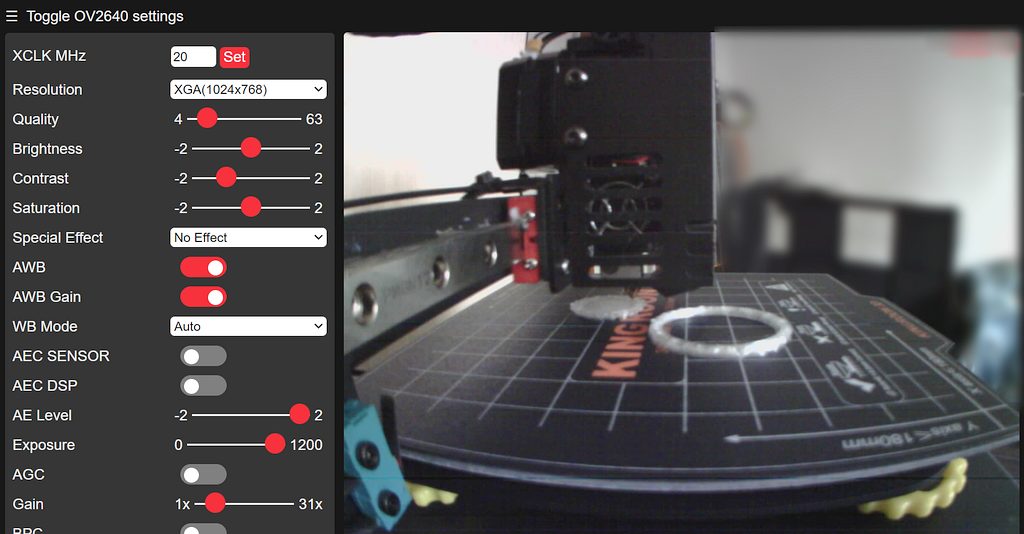

3D printing is a technically complex process where lots of things can go wrong, and quite unexpectedly as well. Make sure to check how your printer is doing at least every 15-30 minutes to catch issues. Or risk ending up with a tangled mess of filament if you leave the process unattended. You can either do this personally or remotely. For the latter, you can make use of some commercially available video monitoring solution or come up with your own cheaper alternative, which is what I went with. I'm using an ESP32-CAM board with a 160° fish-eye lens.

The microcontroller is connected to the home WiFi network and the video feed is available right in the browser.

All of this in total cost me less than $15. How cool is that?

More advanced (and expensive) printers nowadays already come with an integrated camera which can be used via an app or a web-interface control panel.

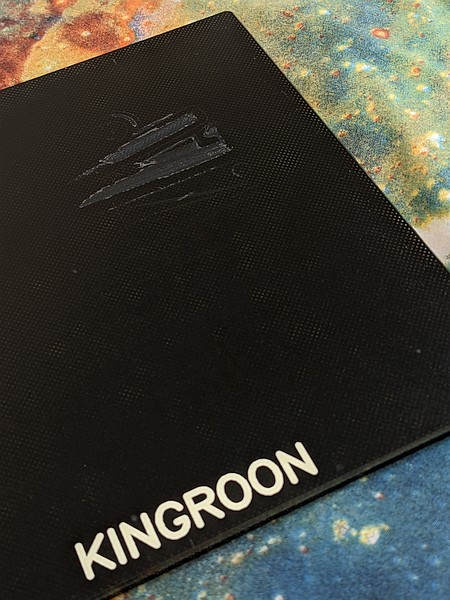

A Word on Glass Print Plates

I'll keep it short: don't buy the glass plate.

Even though I did manage to print 10 or more models on this plate, I was never particularly fond of it.

The magnetic sticker that comes with the printer is perfectly fine and doesn't have strong enough temperature gradient difference across the surface.

Glass plates are considered better in this regard, as they do generally get heated up more evenly than polymer ones, whilst taking a bit longer to heat up to the target temperature… And that's where the pros end and the issues begin: the surface is hard, so any hot end leveling mistake will cause the hot end to permanently damage the specially painted surface of the plate.

Ask me how I know…

In contrast, the standard magnetic sticker that comes with the printer has a bit of "softness" to its matte surface, so it's much more forgiving in that regard. It's also so much harder and more tedious to remove prints from the hard glass plate. As for the sticker — it's flexible and you can actually bend it, which makes print removal a breeze. To compensate for the sticker's tendency to cool down quicker at the corners which might affect first layer adhesion, I usually print at table temperature of 65°C and nozzle temperature of 210°C for PLA, and 75/230°C for PETG, which, believe it or not, sticks to the magnetic sticker bed even better than PLA.

So yeah, just order a default printer kit with the magnetic sticker and don't look back.

Useful Prints

Finally, the fun part. Here are some prints, a couple of which you might want to print on your own device.

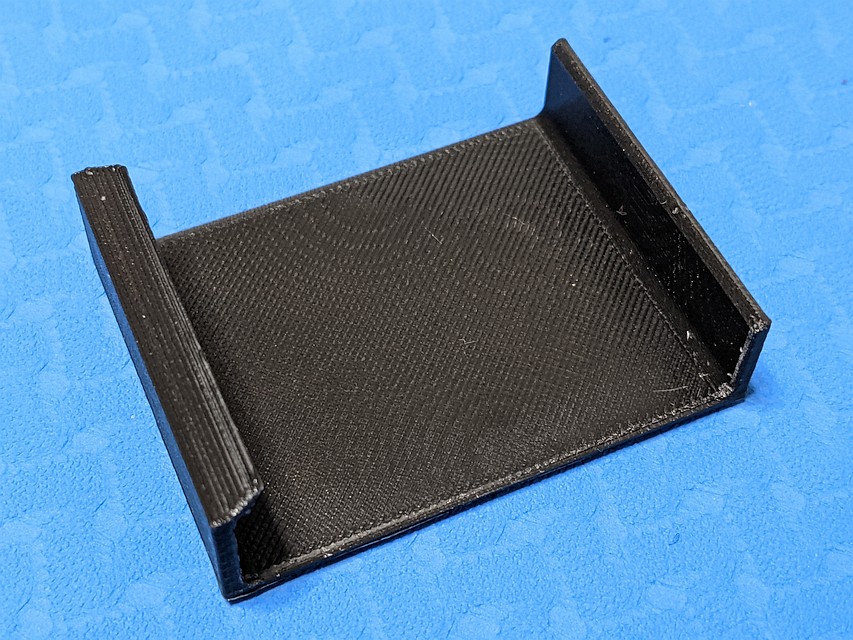

Food Bag Sealing Clips

By now, I believe, the clips need no introduction. They are very strong, snap well and provide reasonable sealing. I've been using a set of clips from half a year ago and they're good as new. Here are the STLs.

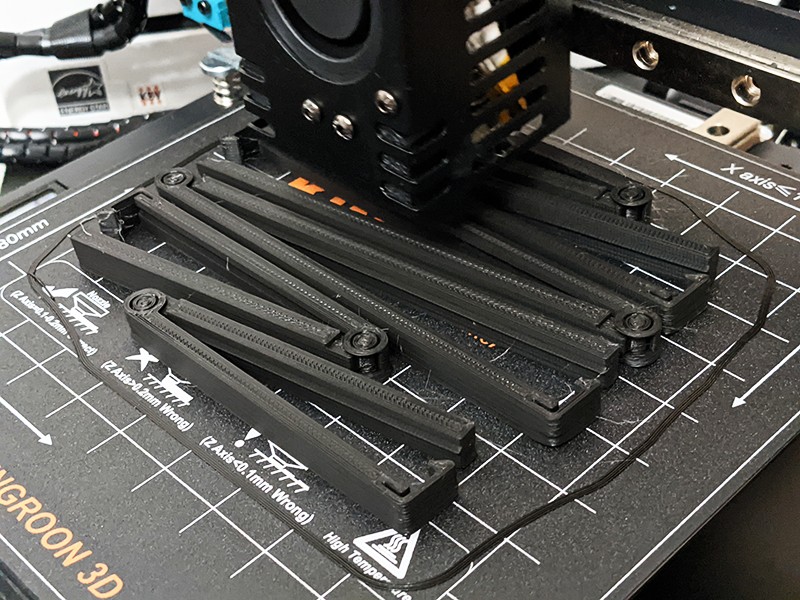

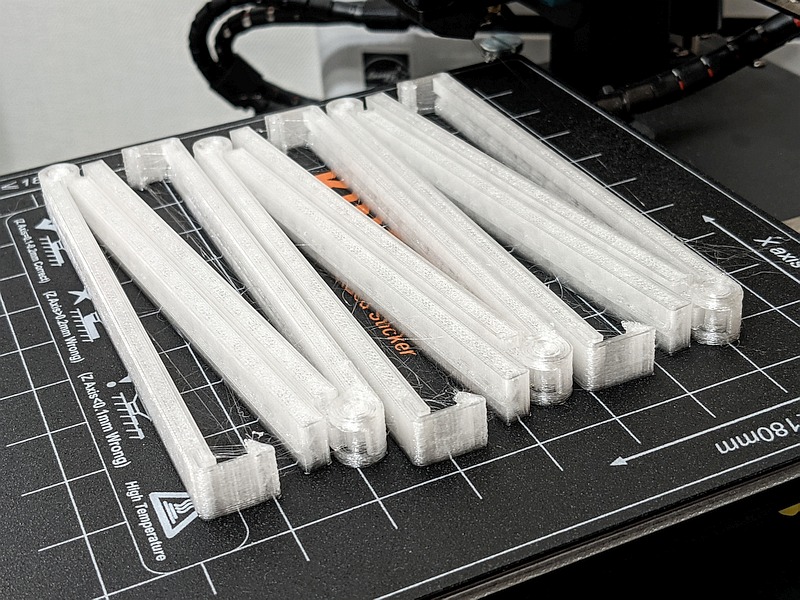

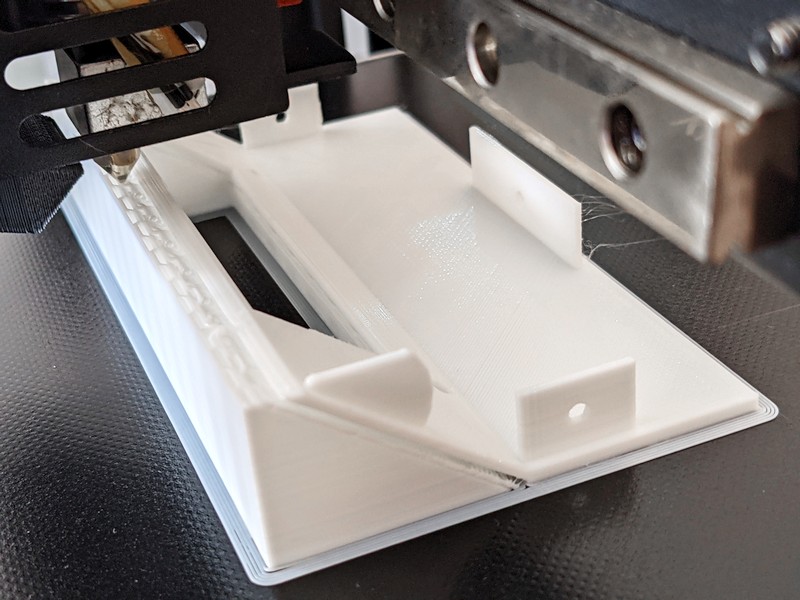

And here's a batch I printed recently with crystal-clear PETG, a material which not only makes for stronger clips, but also looks so cool!

Printing with PETG in most cases creates more stringing compared to PLA. It doesn't affect print quality and is nothing a bit of clean-up can't fix afterwards, or can be mitigated by increasing filament retraction distance to 1.5-2mm or more.

Safety Whistle

Check out "The MakeItLoud V29" whistle, loud enough to make your ears bleed. 118 dB is loud!

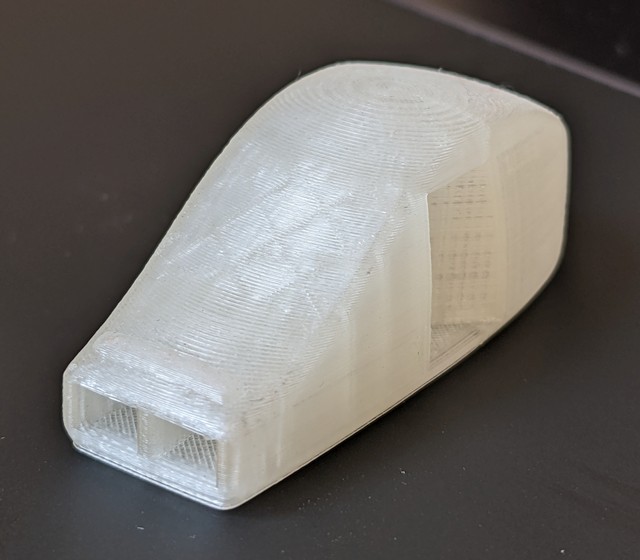

Just for fun I printed this one with translucent (or "natural") PLA which gave it such frosted appearance. I believe everyone should absolutely print and equip this whistle. In case of emergency this thing will make everyone turn your way.

Epson EF-11 Projector Lens Cap

I love my Epson EF-11. It's a compact, short-throw, 1000-lumen 1080p laser projector that I regularly use to play games and watch stuff on a big screen. The funny thing is — it's advertised as a portable projector. Which it absolutely is — it's tiny! There's just one thing Epson omitted that makes little sense if you have experience with their previous models: EF-11 lacks lens cover! The majority of previous compact lamp projector models had an internal cover that you could slide back and forth with a little knob.

Not only does EF-11 lack a sliding cover, it has almost no means of attaching an external one.

Almost.

Luckily, there are ways.

As you can see here, someone beat me to it and created a lens cover that clamps onto the case from below and by the indentation over the lens, and sits pretty tight, providing adequate protection for the lens during transportation. This is an essential mod that basically completes a commercial product.

Custom Stuff

This is where 3D printers truly shine. Here's a short sample of some customized prints that serve specific purpose for my needs.

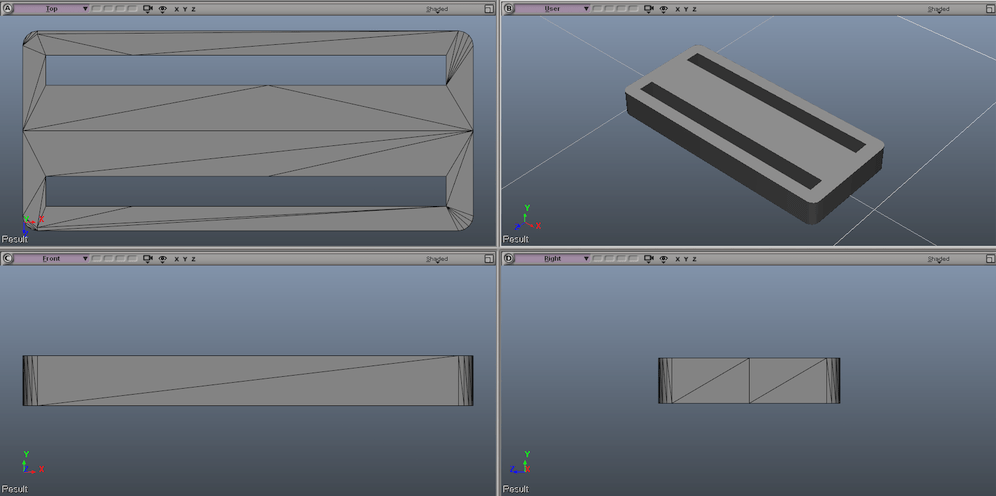

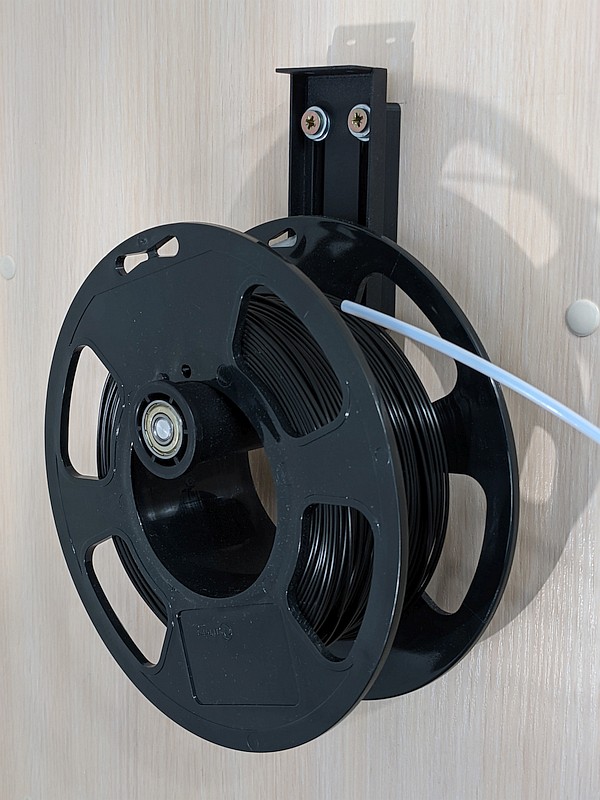

Spool Arm Mount Adaptor

Since KP3D is a direct filament drive printer, the filament needs to be located somewhere above the printer. I decided to buy a filament spool arm and mount it on the wall. The issue is — the arm was meant to be mounted onto a large 3D printer rig. Therefore the other side of the arm protrudes outside the mount, making it difficult to just mount the thing on some vertical surface. To compensate for it, I designed a simple adapter that allowed to place the base of the mount far enough from the surface.

And voilà — the spool sits neatly by the wall, while rotating arm allows it to spin freely during operation.

Safety Water Bottle Holder

People are 60% water. Therefore it makes sense to regularly drink it at a rate of about 2L a day. The problem is — we're often distracted or busy to remember to take a sip or two. The easiest way to fix this is to have a water bottle within reach at all times. Problem solved!

Except… Imagine what would happen if you were sitting in front of your PC, reached for the bottle and accidentally hit it so it tipped over? Nothing good. To minimize the chances of such a disaster happening I designed and printed a custom stand/holder for my water bottle.

The wide base makes it extremely unlikely for the bottle to tip over, so I can rest easy knowing I will not cause a localized flood all over and behind my table.

A… Case? Just a Simple Little Case?

Yep. Even such a simple thing as a small case for orthodontic elastics made my life so much easier. Instead of having to juggle small awkward bags containing tiny elastic rings of different strength every morning and before bed, I placed them into a 2-section case. Equipping elastics to place on my braces is now easier than ever! It took less than a half an hour to design and print, and saved me way more time over the days of its service.

Smart Weather Station

The Alpha and the Omega. The very reason I ended up replacing my crappy old printer with a brand new and more capable one.

You can read the whole story in the related blog post.

… Any Other Custom 3D Printed Mounts And Parts

To summarize, you can apply basic 3D modeling/CAD skills and use your printer to create all sorts of useful mounts for your specific setups:

So… What is a 3D Printer Good For?

Here's a short list of the most notable cases where a 3D printer would prove most useful based on my personal experience with a compact consumer device:

- Improving quality of life with custom adapters or tools

- Producing replacement parts, both temporary and long-term

- Creating custom mounts and adapters

- Surprising friends and relatives with original gifts

- Experimenting and honing 3D modeling/CAD skills whilst applying engineering skills in the real world

If any of these sound useful to you as well, consider taking your first step into the world of 3D printing, for nowadays it's easier than ever, and many consumer-grade 3D printers are even cheaper than traditional ink/laser printers.

September 2024 Update

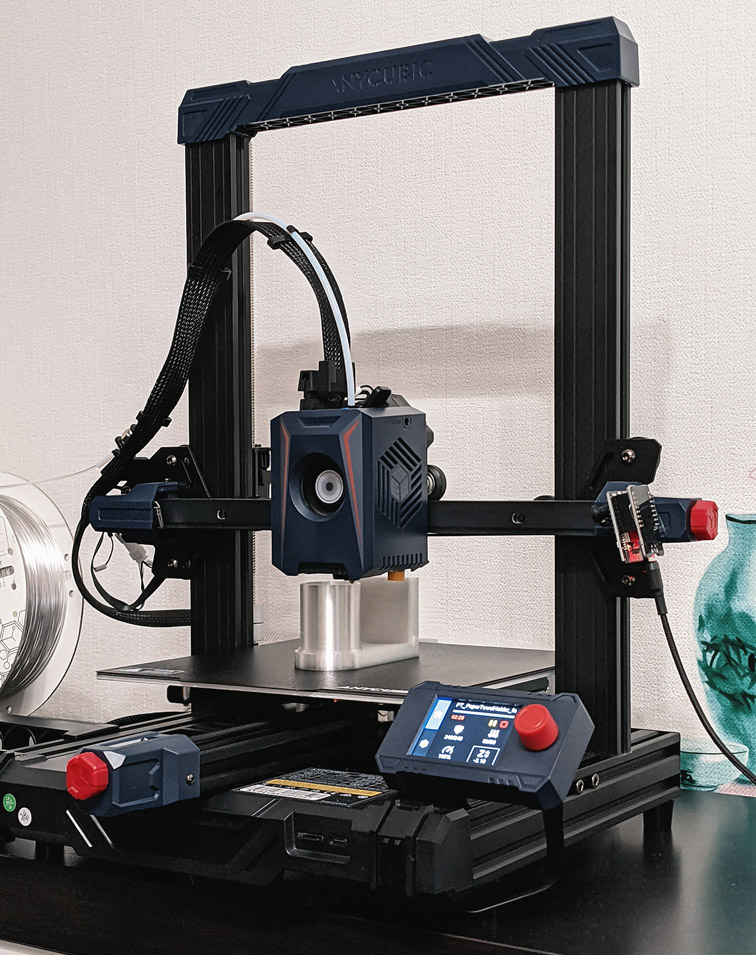

Since I'm regularly trying new things and engineering new devices and tools, I ended up looking for a new 3D printer sooner than I thought I would. And out of sheer curiosity as to what the cheapest possible 3D printer might look like in 2024, and how it would perform, I ended up buying the Anycubic Kobra 2 Neo, which set me back a mere $135 (heavily discounted from $200 due to a random Aliexpress sale happening that month)! For a 3D printer with automatic bed leveling!

And so, after going through a spool of PETG filament (which isn't officially recommended by the manufacturer, but it's nothing a custom Cura profile can't fix) I have to say that it's a very good, no — incredible deal, for the money Anycubic are asking for it. And here's how it looks with my ESP32 CAM attached to it for remote print monitoring:

It's certainly not perfect and comes with very basic firmware, but it gets the job done. Good enough for my needs, that's for sure.

Happy printing!